As the demand for eco-friendly and cost-effective building materials grows, fly ash bricks have become a popular alternative to traditional clay bricks. However, to manufacture high-quality fly ash bricks consistently, one crucial component often gets overlooked — the pallets used in the brick-making process.

In this blog, we’ll explore the importance of Fly Ash Bricks Pallets, their advantages, and why Rajratan Industries is the go-to name for durable and high-performance pallets in India.

What Are Fly Ash Bricks Pallets?

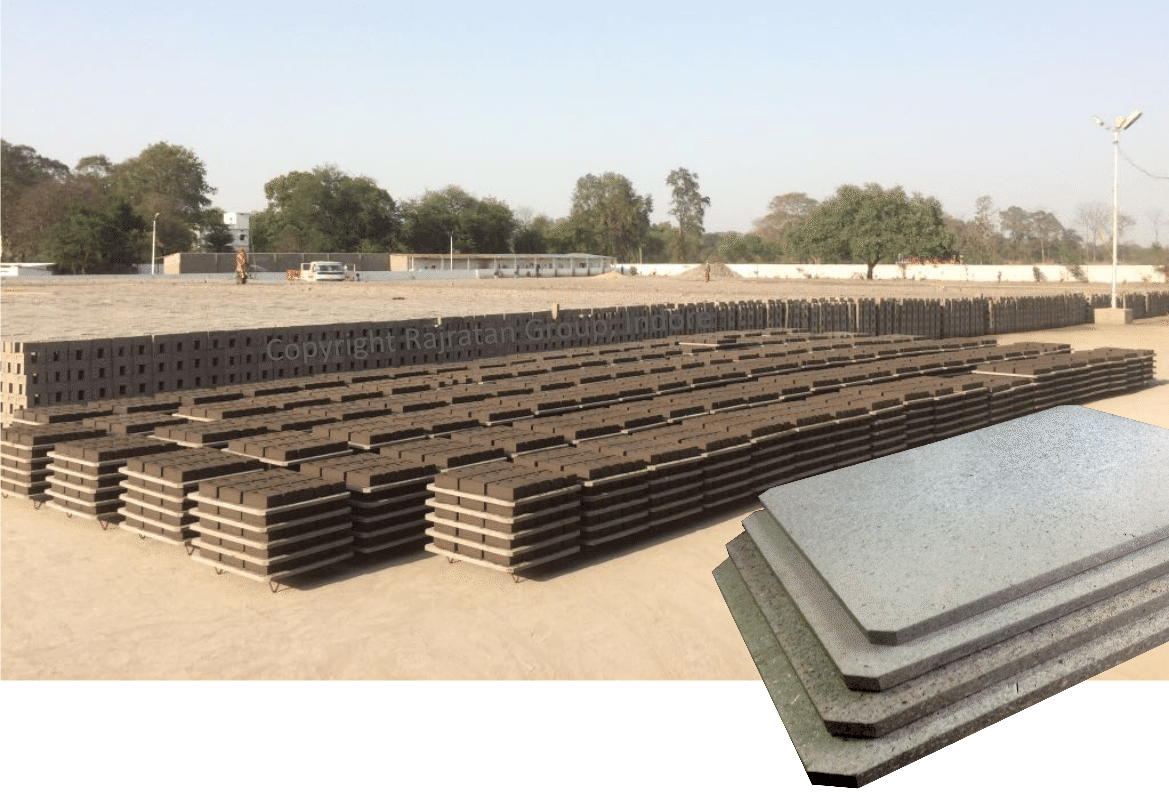

Fly ash bricks pallets are the flat platforms used in the production process to mold, carry, and cure freshly made fly ash bricks. These pallets are placed inside brick-making machines to shape the bricks and are later used for stacking and curing.

The right type of pallet can drastically improve the output quality, curing time, and durability of bricks.

Types of Pallets Used for Fly Ash Bricks

- Plastic Pallets

- Made from high-density recycled plastic

- Lightweight, waterproof, and durable

- Composite Pallets

- Blend of plastic and wood fibers or polymers

- Superior load-bearing capacity

- PVC Pallets

- Smooth surface, ideal for sharp-edged bricks

- Resistant to breakage and cracking

- Wooden Pallets (Traditional)

- Low-cost but short lifespan and prone to moisture damage

Why Choose Plastic or Composite Pallets for Fly Ash Bricks?

✅ High Strength & Load Capacity

Perfectly supports the weight of multiple bricks without bending or cracking.

✅ Moisture & Weather Resistant

Ideal for wet conditions and curing yards, where traditional wooden pallets deteriorate quickly.

✅ Long Life Span

Can be reused hundreds of times, reducing replacement costs.

✅ Smooth Surface Finish

Helps in producing fly ash bricks with clean edges and uniform shape.

✅ Eco-Friendly

Made from recycled materials, helping you meet sustainability goals.

Applications of Fly Ash Bricks Pallets

- Fly ash brick manufacturing plants

- Cement block plants

- Paver block and interlocking tile units

- Curing and stacking yards

- Manual and automatic brick-making machines

Rajratan Industries – India’s Top Manufacturer of Fly Ash Brick Pallets

When it comes to performance and durability, Rajratan Industries leads the industry with its innovative PAC® Pallets designed for fly ash brick manufacturing. Their pallets are trusted by hundreds of brick plants, contractors, and builders across India.

🔷 Why Rajratan PAC® Pallets?

- Engineered using recycled industrial-grade plastic

- Available in custom sizes for different machines

- Proven to withstand high load and pressure

- 100% waterproof, termite-proof, and corrosion-resistant

- Supported by after-sales service and PAN India delivery

🔗 Visit: https://pacproducts.in

Comparison: PAC® Plastic Pallets vs Wooden Pallets

| Feature | PAC® Plastic Pallets | Wooden Pallets |

|---|---|---|

| Lifespan | ✅ 1000+ uses | ❌ 100–200 uses |

| Water Resistance | ✅ Excellent | ❌ Poor |

| Maintenance | ✅ Minimal | ❌ High |

| Environmental Impact | ✅ Recycled material | ❌ Tree cutting |

| Brick Quality Output | ✅ High consistency | ❌ May warp |

Conclusion

Fly Ash Bricks Pallets are more than just accessories – they’re the foundation of your production process. Choosing the right pallet ensures better quality bricks, faster production, and long-term savings.

If you’re looking for reliable, durable, and eco-friendly pallets for your fly ash brick unit, Rajratan Industries has the perfect solution with its PAC® brand of plastic and composite pallets.

Get in Touch with Rajratan Industries

📍 Website: https://pacproducts.in

📧 Email: info@pacproducts.in

📞 Phone: +91-7880008227 (Insert contact)

Upgrade your brick plant with high-performance Fly Ash Brick Pallets today!