The Ultimate Guide to Plastic Shuttering Boards

Shuttering boards, also known as formwork boards, are essential in construction for molding and shaping concrete structures. Traditionally, plywood was the go-to material for shuttering due to its affordability and availability. However, with the rise of sustainable and durable solutions, plastic shuttering boards have emerged as the superior alternative. In this blog, we delve into the features, benefits, and applications of plastic shuttering boards and why they are revolutionizing the construction industry.

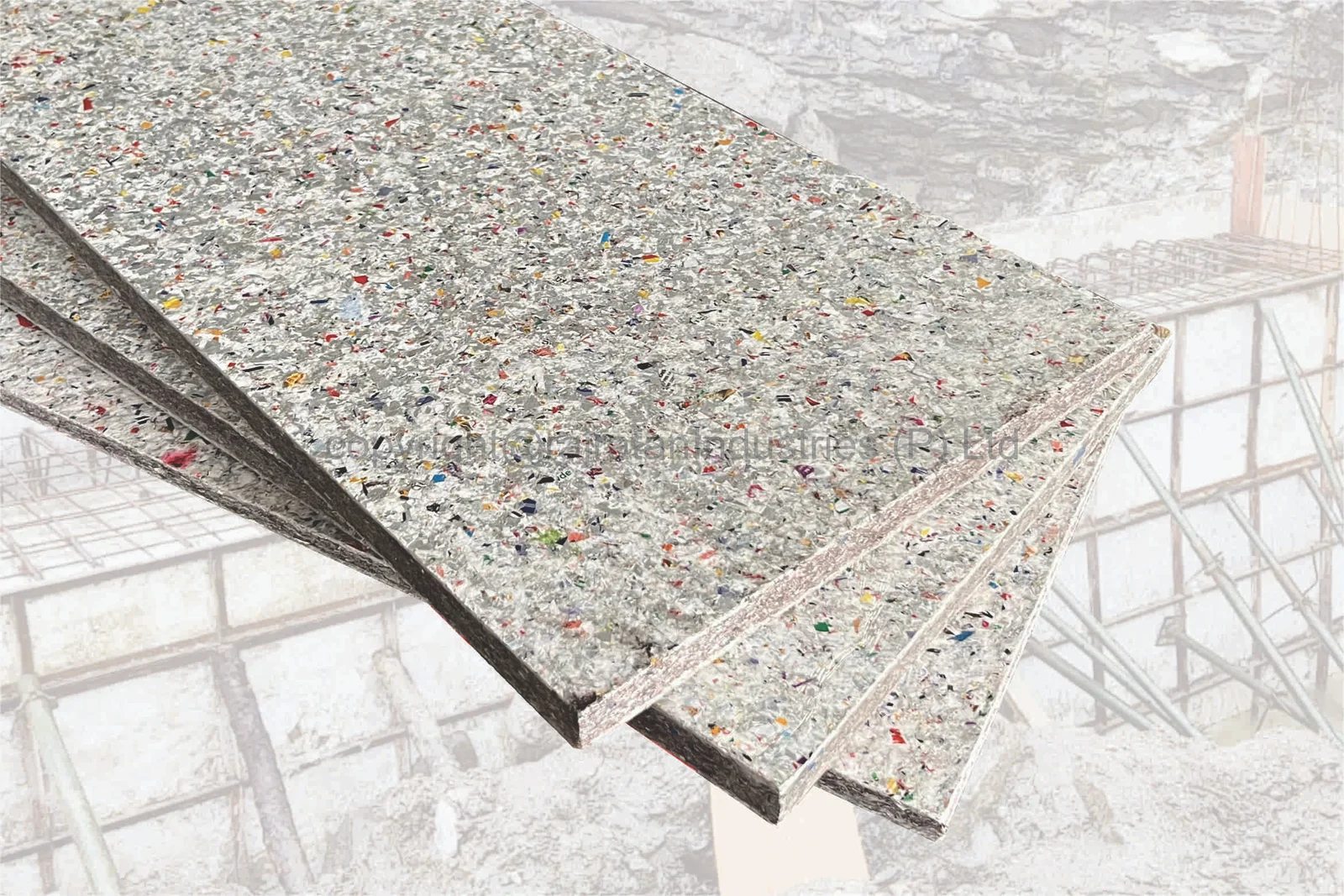

What Are Plastic Shuttering Boards?

Plastic shuttering boards are made from high-quality, recycled industrial-grade plastics, offering a modern, eco-friendly alternative to traditional plywood. These boards are designed to provide strength, durability, and reusability, making them ideal for a wide range of construction applications.

Why Choose Plastic Shuttering Boards Over Plywood?

While plywood has been a staple material in formwork for years, it comes with limitations such as susceptibility to water damage, warping, and limited reusability. Plastic shuttering boards address these challenges with:

- Superior Durability: Plastic boards are resistant to water, weather, and chemicals, ensuring a longer lifespan.

- Eco-Friendliness: Made from recycled materials, they help reduce environmental impact.

- Cost-Effectiveness: Their reusability and longevity lower the overall material costs.

- Lightweight and Easy to Handle: Simplifies transportation and installation.

Applications of Plastic Shuttering Boards

Plastic shuttering boards are versatile and can be used across various construction projects, including:

- Wall and Slab Formwork: Achieve smooth, precise surfaces for walls and slabs.

- Road and Drainage Systems: Perfect for shaping gutters and roads.

- Precast Concrete: Ideal for casting precast concrete elements like beams and panels.

- Complex Structures: Suitable for engineered constructions like bridges and tunnels.

Advantages of Plastic Shuttering Boards

Here’s why plastic shuttering boards are becoming the go-to choice for construction professionals:

- Long Lifespan: Resistant to damage from moisture, weather, and heavy use.

- Sustainability: Promotes eco-friendly construction by repurposing industrial plastic waste.

- Enhanced Safety: Provides stable and reliable support during construction.

- Smooth Finish: Reduces the need for additional surface treatment, saving time and labor.

- No Warping or Splintering: Unlike plywood, plastic boards maintain their integrity over multiple uses.

Why Rajratan Plastic Shuttering Boards Are the Best Choice

Rajratan, a leader in sustainable solutions, offers premium plastic shuttering boards designed to meet the diverse needs of modern construction. Key features of Rajratan’s plastic shuttering boards include:

- Customized Solutions: Boards can be tailored to specific requirements.

- High Strength and Load Capacity: Supports heavy concrete structures with ease.

- Reusability: Lasts for multiple construction cycles, significantly reducing costs.

Tips for Using Plastic Shuttering Boards

Maximize the benefits of plastic shuttering boards with these practical tips:

- Clean After Use: Wash off concrete residues to maintain performance.

- Store Properly: Keep in a dry and secure place to prevent damage.

- Inspect Regularly: Check for cracks or wear to ensure safety and efficiency.

Conclusion

Plastic shuttering boards are redefining the construction landscape by offering a sustainable, durable, and cost-effective alternative to traditional plywood. Rajratan’s high-quality plastic shuttering boards combine innovation and environmental responsibility, making them the ideal choice for any construction project.

Upgrade your construction practices with Rajratan’s Plastic Shuttering Boards. Contact us today to learn more about how we can help you build smarter and greener!